Green Flying Revolution: How Sustainable Aviation Fuel (SAF) is Transforming Aviation in 2025

The year 2025 marks a historic turning point for global aviation. With the European Union’s ReFuelEU Aviation mandate now requiring 2% blending of Sustainable Aviation Fuel (SAF) at major airports, the industry has crossed the threshold from voluntary sustainability initiatives to legally mandated environmental action. This transformation affects every aviation professional—from pilots and flight attendants to ground crew and engineers—and signals the beginning of the most significant fuel revolution since the jet age began.

For aviation personnel worldwide, SAF represents both an operational reality and a pathway to environmental responsibility. Unlike experimental technologies still decades away, SAF is being used today in commercial operations while offering substantial emissions reductions of up to 85%. This comprehensive guide explains why 2025 is crucial for the adoption of SAF and what this transformation means for aviation professionals and the broader public.

The 2025 Regulatory Revolution: ReFuelEU Aviation Takes Flight

Mandatory Blending Requirements Begin

The European Union’s ReFuelEU Aviation regulation, implemented January 1, 2025, establishes the world’s most ambitious SAF mandate. This legislation requires fuel suppliers at EU airports with more than 800,000 passengers or 100,000 tonnes of freight annually to provide at least 2% SAF in their fuel mix. The mandate applies to all flights departing from these airports, regardless of the airline’s nationality, creating unprecedented global reach.

The regulation follows an aggressive escalation timeline designed to drive industry transformation:

- 2% SAF in 2025

- 6% by 2030

- 20% by 2035

- 34% by 2040

- 70% by 2050

Beyond the headline blending requirements, ReFuelEU includes specific provisions for synthetic e-SAF, which must comprise 0.7% of fuel supply by 2030 and rise to 35% by 2050. This dual approach ensures both immediate adoption of available SAF technologies and long-term development of next-generation synthetic fuels.

Global Market Impact and Production Scaling

According to IATA, global SAF production is expected to double by 2025, reaching 2 million tonnes, which will represent just 0.7% of aviation’s total fuel consumption. While this doubling demonstrates significant momentum, it also highlights the massive scaling challenge ahead. The expected production increase is expected to add $4.4 billion to the global aviation fuel bill in 2025.

Industry projections suggest SAF production capacity could reach 18 million tonnes by 2030 if announced projects proceed on schedule. However, achieving the volumes needed for long-term decarbonization requires unprecedented industrial scaling and technological innovation.

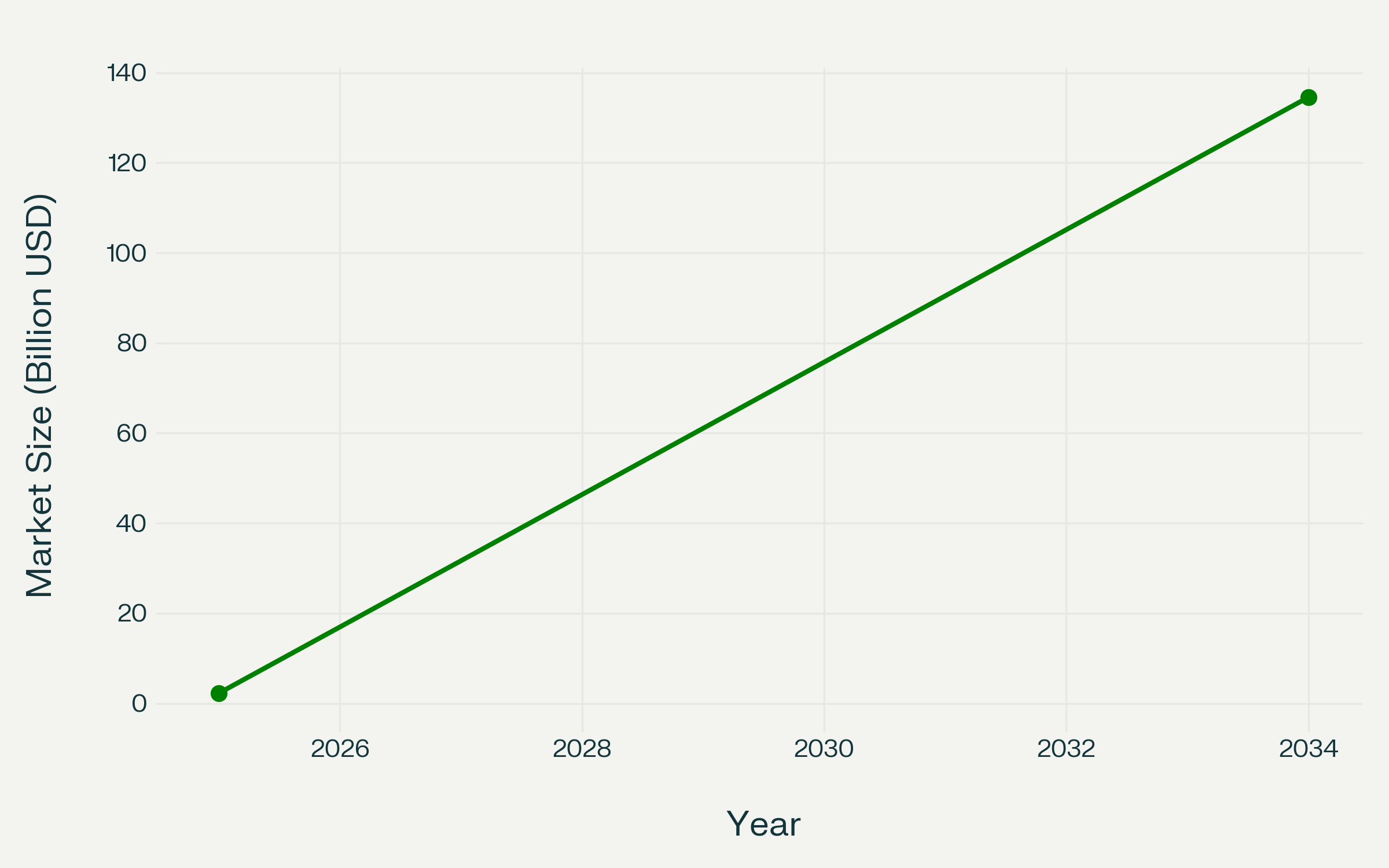

Global SAF Market Growth (2025–2030)

Source: Precedence Research, 2025

Understanding SAF Technology: Four Pathways to Sustainability

HEFA: The Current Market Leader

Hydroprocessed Esters and Fatty Acids (HEFA) technology dominates today’s commercial SAF market, accounting for over 95% of all SAF-powered flights. This proven pathway refines waste oils, animal fats, and vegetable oils through hydrogenation processes, achieving approximately 75% lifecycle CO2 reduction compared to conventional jet fuel.

HEFA’s strength lies in its maturity and economic viability, but industry experts warn of an approaching “HEFA tipping point” after 2030. As demand grows, the available supply of waste oil feedstocks will become insufficient, necessitating diversification to alternative production pathways.

Alcohol-to-Jet (AtJ): Agricultural Waste Conversion

AtJ technology converts alcohols, such as ethanol and isobutanol, into SAF through deoxygenation and molecular bonding processes. Using feedstocks such as agricultural residues and non-food crops, AtJ typically achieves 85% emissions reductions without competing with food production systems.

Fischer-Tropsch: Municipal Waste to Aviation Fuel

Gasification, combined with Fischer-Tropsch synthesis, converts municipal solid waste and forestry residues into SAF, achieving up to 90% CO2 reduction. This approach supports circular economy principles by transforming waste streams into valuable aviation fuel while reducing landfill burdens.

Power-to-Liquid (e-SAF): The Ultimate Renewable Solution

e-SAF represents the most promising long-term technology, producing synthetic fuel from captured CO2 and green hydrogen. With potential for 95% emissions reduction, e-SAF could theoretically provide unlimited production capacity using renewable electricity and atmospheric CO2.

Projected Global SAF Production Volume (2024–2030)

Source: IATA, SkyNRG, ACI Europe (2025).

Operational Impact for Aviation Professionals

Flight Deck Operations: Seamless Integration

Due to its “drop-in” nature, SAF integration brings minimal operational changes for pilots. Certified SAF meets identical ASTM D7566 and D1655 specifications as conventional Jet A-1, ensuring identical performance characteristics. Pratt & Whitney has successfully tested nine different engine models on 100% SAF since 2022, demonstrating complete compatibility.

- Fuel density variations: Some SAF blends may have slightly different densities, requiring minor fuel planning adjustments

- Documentation requirements: Flight release forms now indicate the SAF percentage for regulatory compliance

- Performance monitoring: Airlines track fuel efficiency and engine performance data on SAF flights

Cabin Crew: Sustainability Ambassadors

Flight attendants play increasingly essential roles in SAF awareness and passenger education. Airlines report that flights using SAF achieve improved Net Promoter Scores when crew members make announcements about environmental benefits. Many carriers now include SAF information in pre-flight briefings, positioning cabin crew as sustainability ambassadors.

Ground Operations: Enhanced Documentation

Ground staff and fuel handlers work with SAF using identical safety procedures as conventional fuel, maintaining the same flash points and hazard profiles. However, increased documentation and chain-of-custody tracking requirements mean ground crews must understand SAF certification and compliance procedures.

Economic Realities and Cost Challenges

Price Premium and Compliance Costs

SAF pricing remains the most significant adoption barrier, with costs 3-5 times higher than conventional Jet A-1 fuel in 2025. The EU mandate compliance adds substantial costs beyond market prices. For the estimated 1 million tonnes of SAF needed to meet European mandates in 2025, the market cost is projected to be $1.2 billion, with additional compliance fees adding $1.7 billion.

Supply Shortage and Market Dynamics

Current SAF production accounts for just 0.3% of global jet fuel consumption, totalling approximately 1.25 billion litres. To meet airline net-zero targets and government mandates, the industry needs over 450 billion litres—more than 350 times current production.

Environmental Benefits and Sustainability Impact

Greenhouse Gas Reduction

SAF delivers substantial environmental benefits, reducing lifecycle greenhouse gas emissions by 70-85% compared to conventional jet fuel, depending on feedstock and production pathway. The most advanced e-SAF technologies can achieve up to a 95% reduction in emissions.

Circular Economy Benefits

SAF production supports circular economy principles by converting waste materials into valuable aviation fuel. Used cooking oil, agricultural residues, municipal waste, and forestry byproducts become feedstocks for sustainable fuel production.

Industry Leadership and Innovation

Airline Pioneering Programs

Leading airlines demonstrate practical SAF adoption strategies. Virgin Atlantic completed the world’s first 100% SAF transatlantic flight in November 2023, using a unique dual blend of 88% HEFA and 12% synthetic aromatic kerosene. This historic flight demonstrated SAF’s capability as a complete replacement for fossil fuels in long-haul operations.

Manufacturing Commitments

Aircraft and engine manufacturers actively support SAF adoption. Boeing commits to delivering 100% SAF-capable aircraft by 2030, while Airbus integrates SAF into delivery flights across its global manufacturing network. Engine manufacturers, including Pratt & Whitney and Rolls-Royce, conduct extensive 100% SAF testing programs, paving the way for eliminating blending requirements.

Future Outlook: Scaling Toward Net-Zero

Technology Roadmap

The pathway to aviation’s net-zero target by 2050 depends heavily on SAF scaling and cost reduction. Industry analysis suggests SAF could contribute 65% of required emissions reductions, with the most significant acceleration expected in the 2030s as production scales and technologies mature.

Market Development

The global SAF market is projected to grow from $2.06 billion in 2025 to $25.62 billion by 2030, representing a compound annual growth rate of 65.5%. Regulatory mandates, voluntary airline commitments, and increasing investment in production technologies drive this explosive growth.

Practical Guidance for Aviation Professionals

For Pilots

- Review the company’s SAF briefing materials and understand fuel documentation requirements

- Monitor fuel planning software for density-corrected calculations on high-SAF blends

- Report any unusual fuel system observations to engineering teams

- Stay informed about SAF usage percentages and environmental benefits

For Flight Attendants

- Prepare for passenger questions about SAF and sustainability initiatives

- Practice brief, positive announcements about SAF usage on applicable flights

- Understand airline sustainability programs and passenger participation options

- Recognise SAF flights as opportunities to enhance customer satisfaction

For Ground Staff

- Maintain identical safety procedures for SAF handling as conventional fuel

- Ensure proper documentation of SAF percentages and certification requirements

- Monitor supply chain logistics for SAF delivery and blending operations

- Support chain-of-custody requirements for sustainability verification

Frequently Asked Questions (FAQ)

What exactly is Sustainable Aviation Fuel (SAF)?

SAF is jet fuel produced from renewable feedstocks like waste oils, agricultural residues, or captured CO2. It meets identical technical specifications to conventional Jet A-1 fuel but reduces lifecycle greenhouse gas emissions by 70-95% depending on the production pathway.

Can aircraft fly safely on 100% SAF?

Yes, extensive testing by aircraft manufacturers and engine companies confirms that properly certified SAF can safely power aircraft at 100% concentration. Virgin Atlantic and other airlines have completed 100% SAF flights. However, current regulations limit commercial blending to 50% until formal 100% certification is complete.

How does SAF affect day-to-day flight operations?

SAF has minimal impact on flight operations as it’s a “drop-in” fuel that functions identically to conventional fuel. Minor fuel planning adjustments may be necessary to account for density differences, and documentation now includes reporting of SAF percentage for compliance purposes.

Why is SAF so expensive compared to regular jet fuel?

Limited production capacity, complex supply chains, and compliance costs make SAF 3-5 times more expensive than conventional fuel in 2025. Costs are expected to decrease significantly as production scales up and technologies mature through the 2030s.

Do crew members need special training for SAF operations?

Basic SAF operations do not require specialised training since it is a drop-in fuel. However, airlines are updating crew education to include SAF awareness, environmental benefits, and passenger communication about sustainability initiatives.

How can aviation professionals support SAF adoption?

Stay informed about airline SAF programs, educate passengers about environmental benefits, provide feedback on operational experiences, and advocate for sustainable flying initiatives whenever possible.

What’s the difference between e-SAF and other types of SAF?

e-SAF is produced using captured CO2 and green hydrogen powered by renewable electricity. Unlike other SAF types that use biological feedstocks, e-SAF has virtually unlimited scaling potential and can achieve a 95% reduction in emissions.

Will SAF eventually replace all conventional jet fuel?

Industry goals under EU mandates target 70% SAF by 2050, with similar ambitions globally. Complete replacement depends on production scaling, cost reduction, and technological advancement, particularly in e-SAF production capacity.

Conclusion: The Green Revolution Takes Flight

2025 marks a watershed moment for aviation sustainability, as SAF transitions from experimental technology to a regulatory requirement. The EU’s ReFuelEU mandate catalyses global transformation, creating demand certainty that drives investment and innovation across the entire SAF value chain.

This transformation brings new responsibilities and opportunities for aviation professionals. Pilots, flight attendants, and ground crew become sustainability advocates while maintaining the highest safety standards. The industry’s commitment to achieving net-zero emissions by 2050 relies on continued collaboration among airlines, fuel producers, manufacturers, and regulatory bodies.

The road ahead requires massive production scaling, cost reduction, and technological innovation. However, the foundation is strong: SAF works safely in existing aircraft, provides substantial environmental benefits, and enjoys growing political and industry support. As production volumes increase and costs decline, SAF will become an increasingly viable solution for aviation’s environmental challenges.

The green revolution in aviation has begun, driven by renewable feedstocks and regulatory mandates. For every industry professional, 2025 marks the start of a new era where environmental responsibility and operational excellence go hand in hand.

Sources and References

- Neste – ReFuelEU Aviation Explained

- US Trade.gov – EU Aerospace SAF Regulation

- ESG Today – Global SAF Production to Double

- Azzera – ReFuelEU Handbook 2025

- GEODIS – EU SAF Mandate Guide

- Markets and Markets – SAF Market 2025-2030

- Synhelion – SAF Regulation Overview

- BP – ReFuelEU SAF Mandate

- SIA Partners – SAF Production Pathways

- Hydrogen Europe – e-SAF Policy Needs

- Climate Change News – E-SAF Development

- Agrioil – SAF from Used Cooking Oil

- World Energy – SAF 101 Introduction

- TTG Asia – IATA SAF Costs Warning

- Virgin Atlantic – 100% SAF Flight

- United Airlines – SAF Program

- Fastmarkets – SAF Mandates 2025

- CSO Futures – SAF Production Doubling

- Khaitan Bioenergy – Environmental Benefits

- CarbonClick – SAF Emissions Reduction

- IBA Aero – Aviation Sustainability Costs

- Pratt & Whitney – 100% SAF Testing

- SkyNRG – SAF Market Outlook 2025

- Synhelion – SAF Products